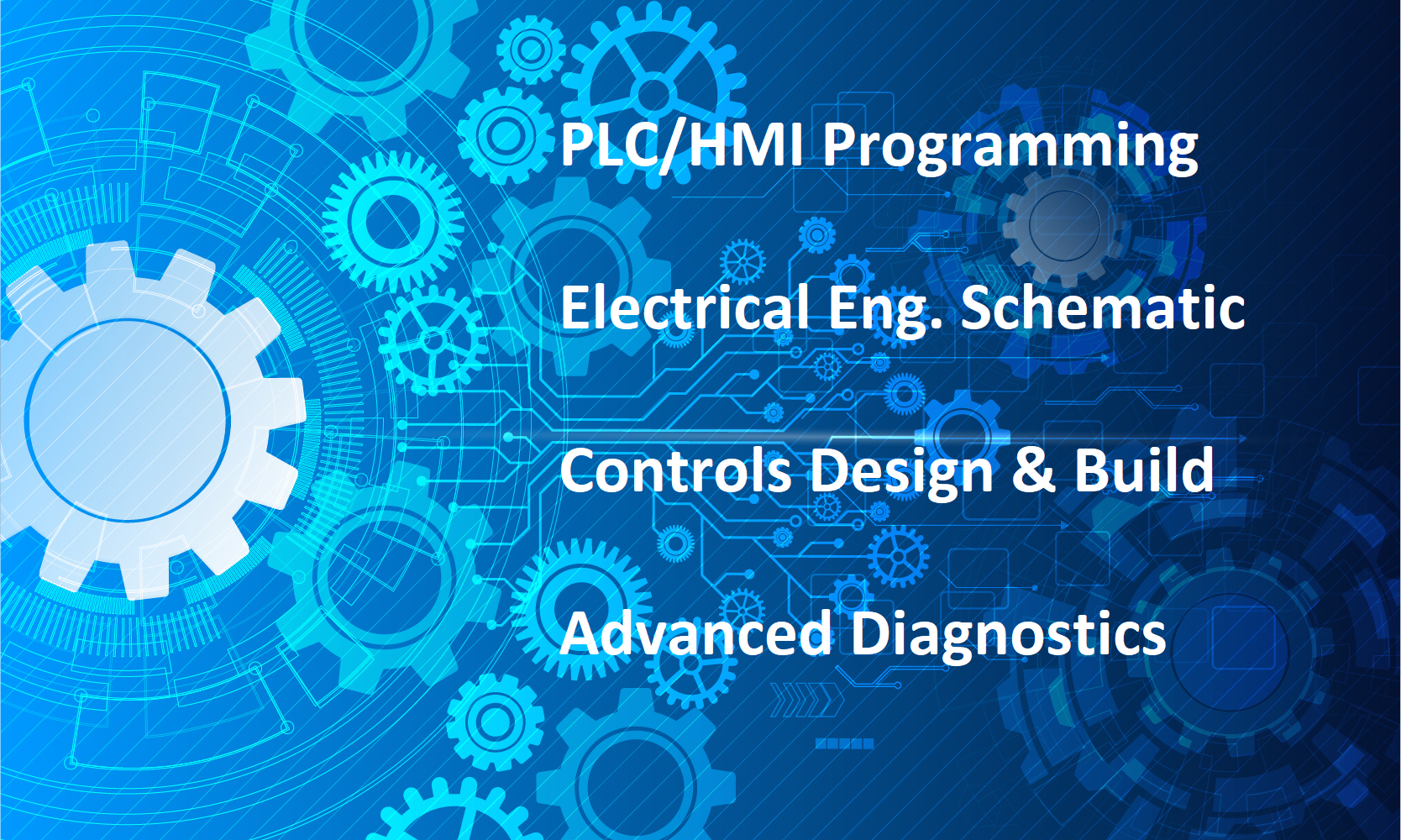

at Ox Controls we Specialize in all things Automation. with over 18 years of experience in FDA regulated Manufacturing, including food and beverage as well as Pharmaceuticals and Nutraceuticals. We also have extensive experience in most Industrial Manufacturing Processes from Equipment design and build, to Home Automation products and installation. Our field services and R&D are second to none.

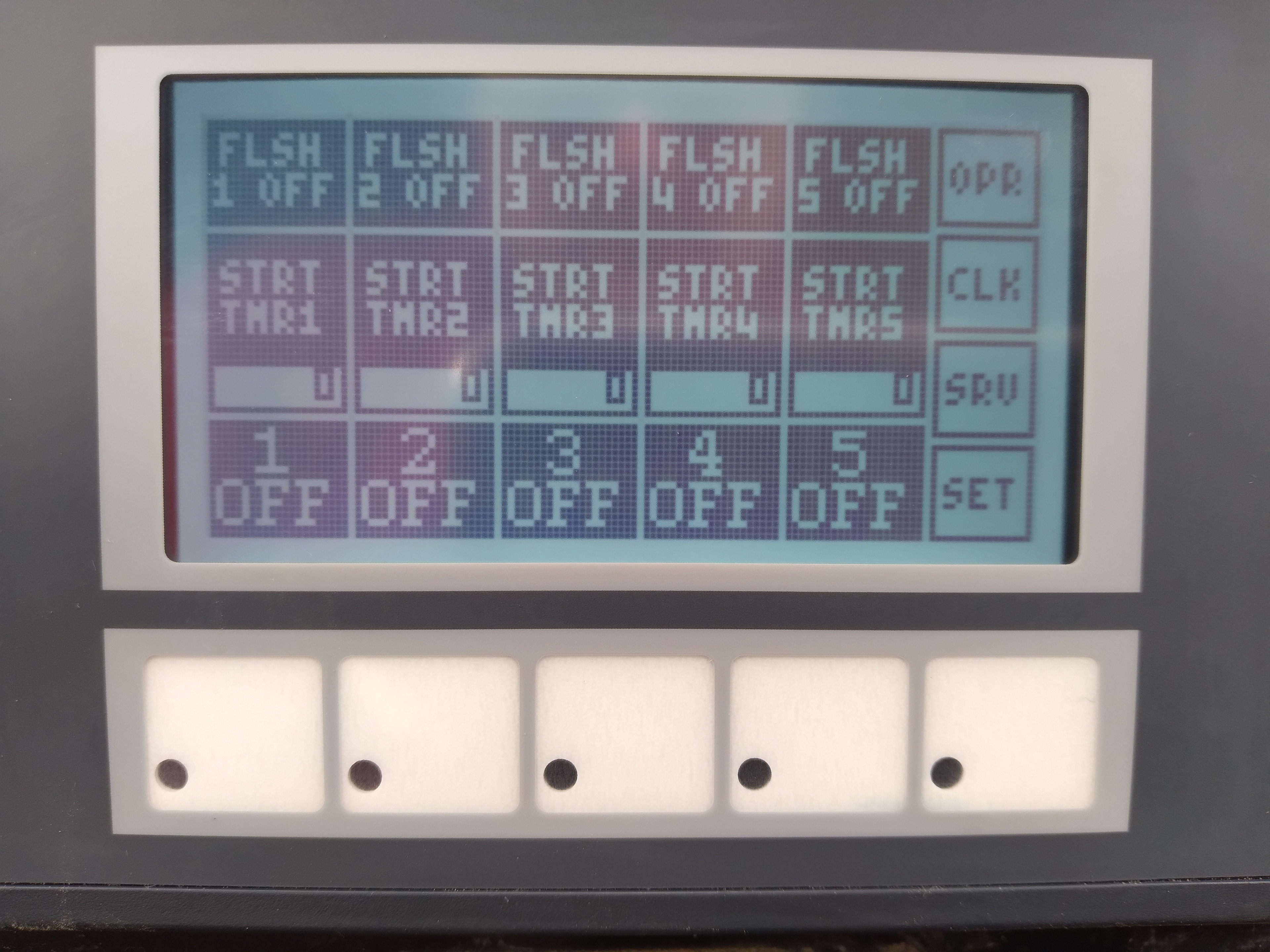

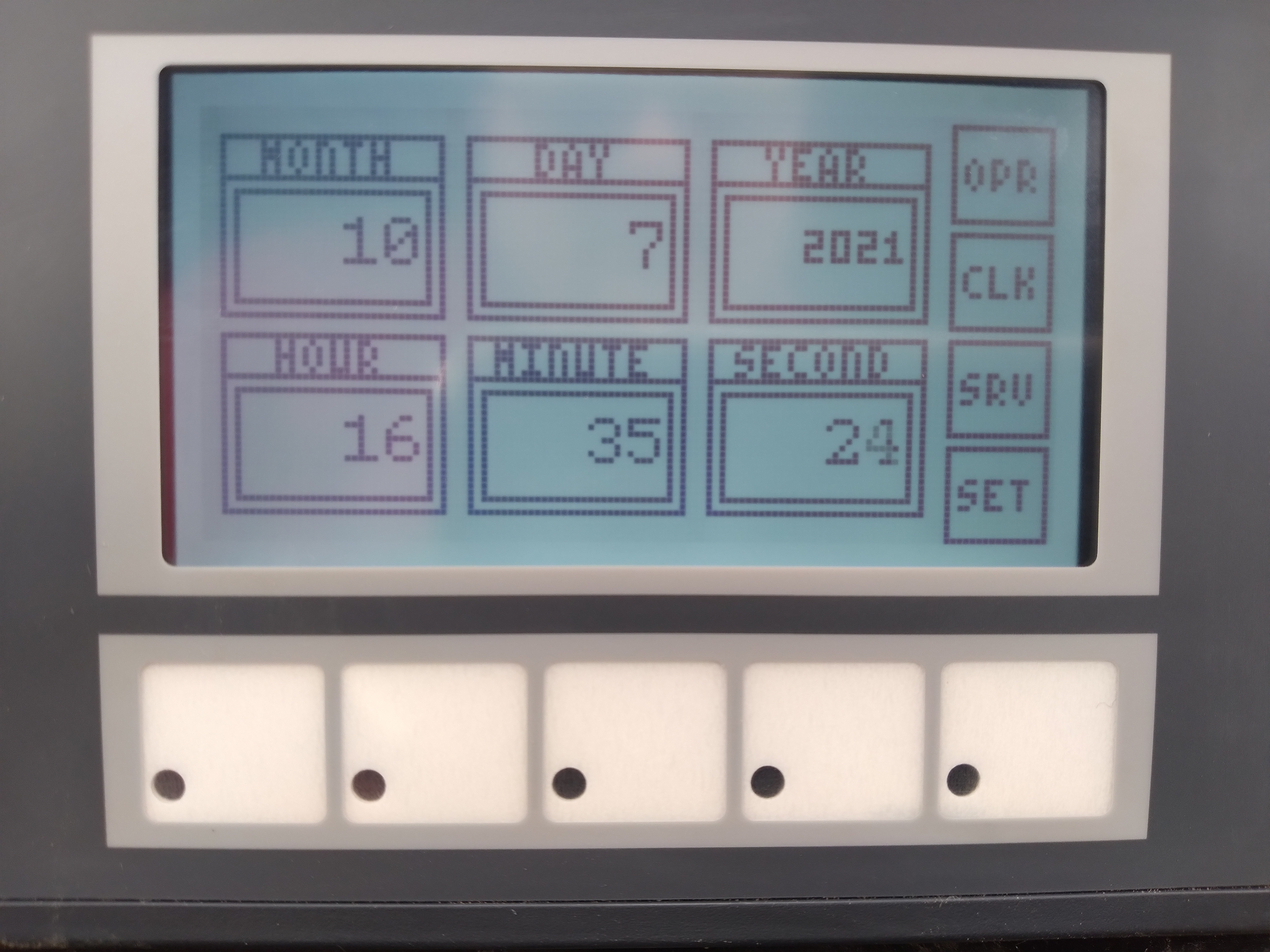

The OX controller is a durable UTV/4X4 Auxiliary component controller for lightbars, winches, dump beds Etc...

OX controller hardware

OX controller

home screen

LOGO

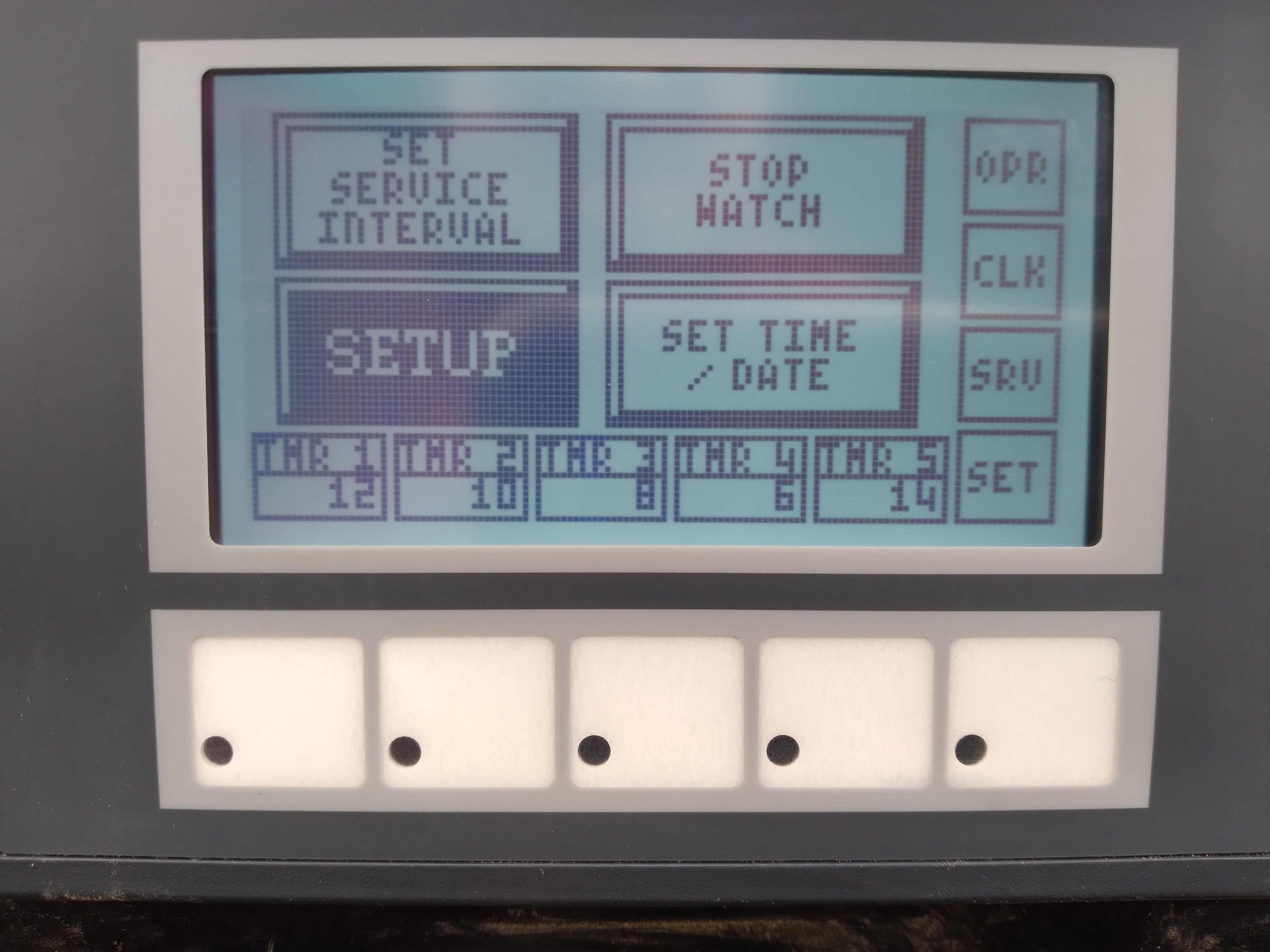

set calendar/clock

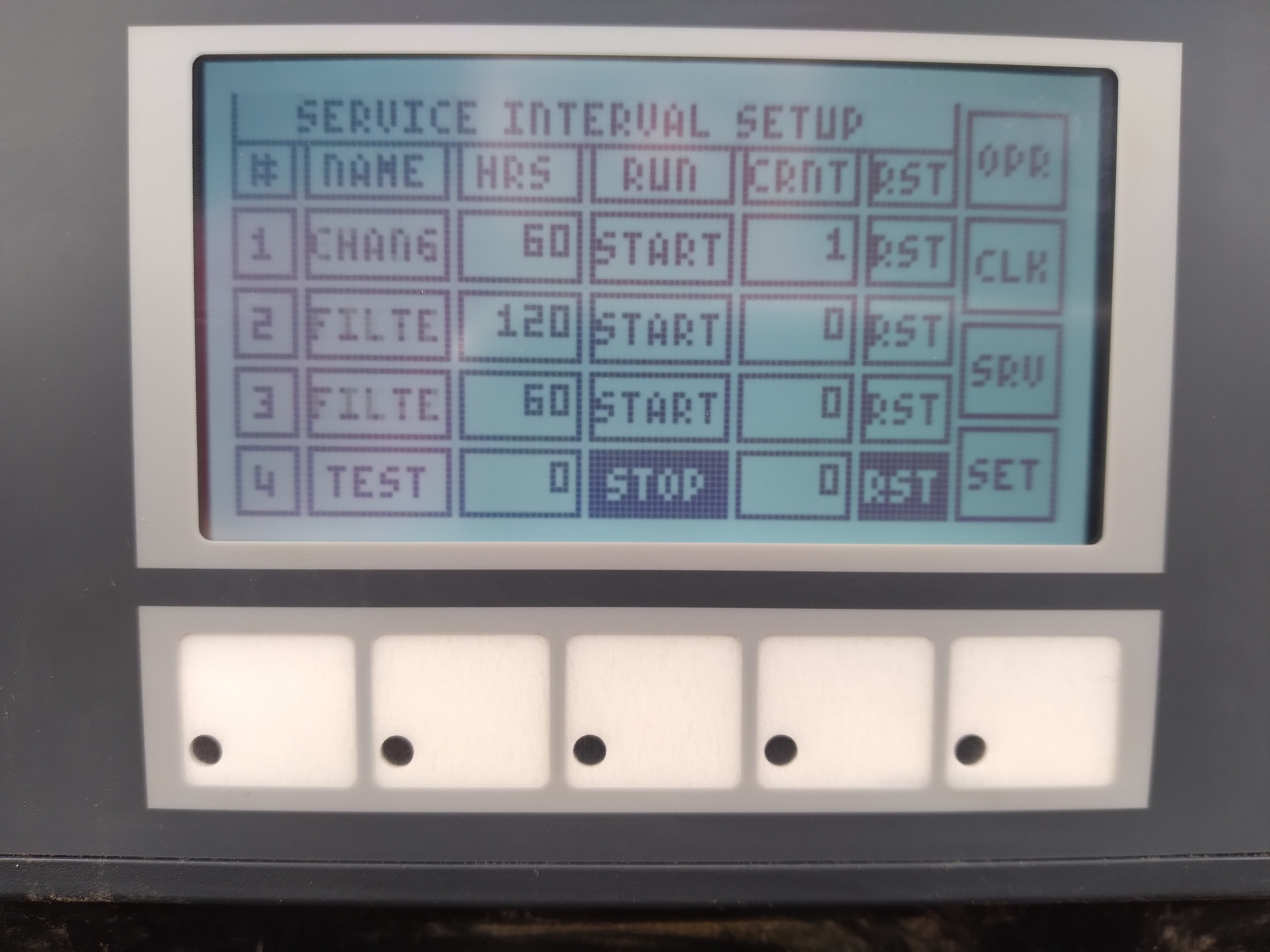

service interval set

user screen

stopwatch screen

Information

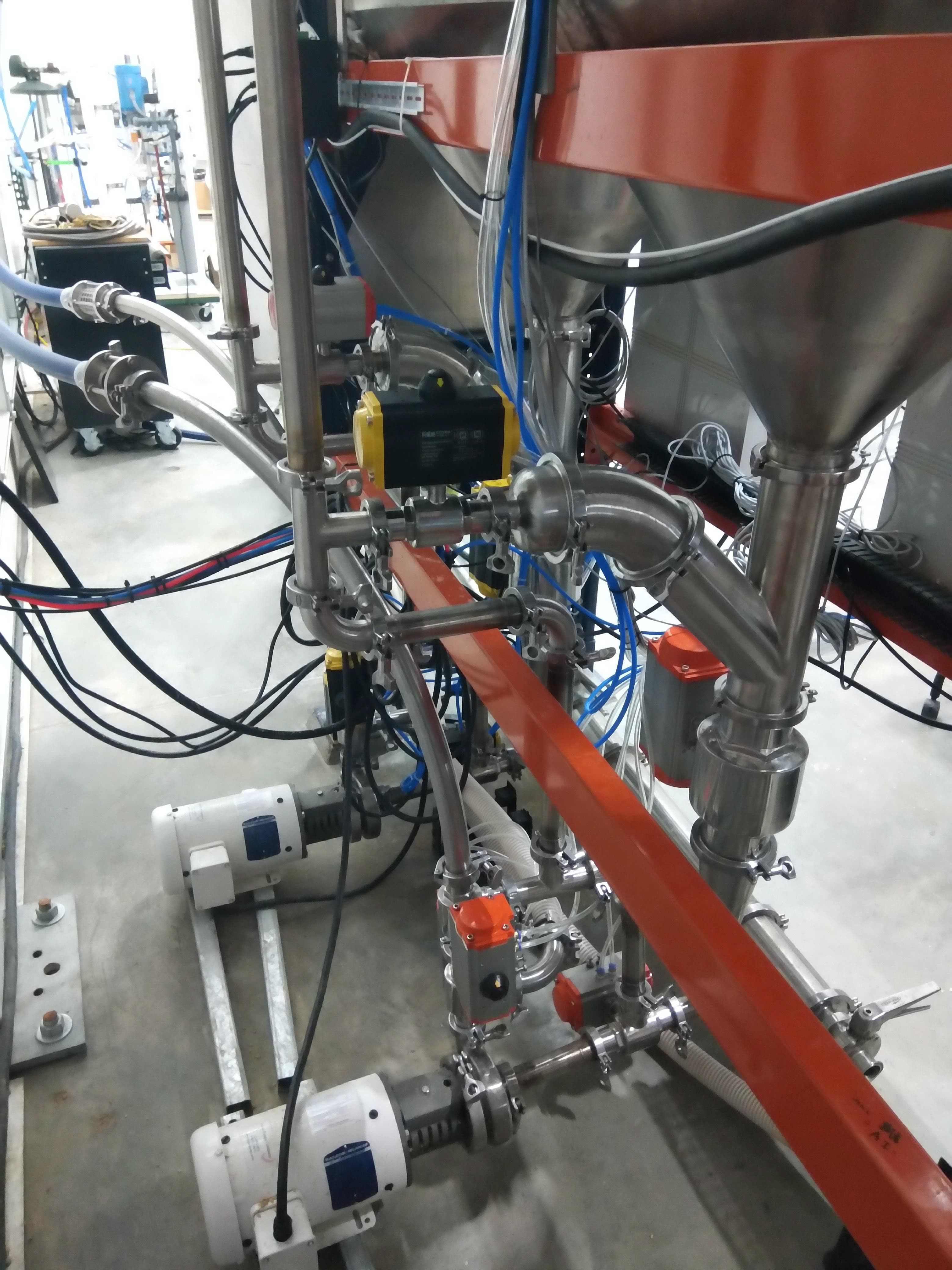

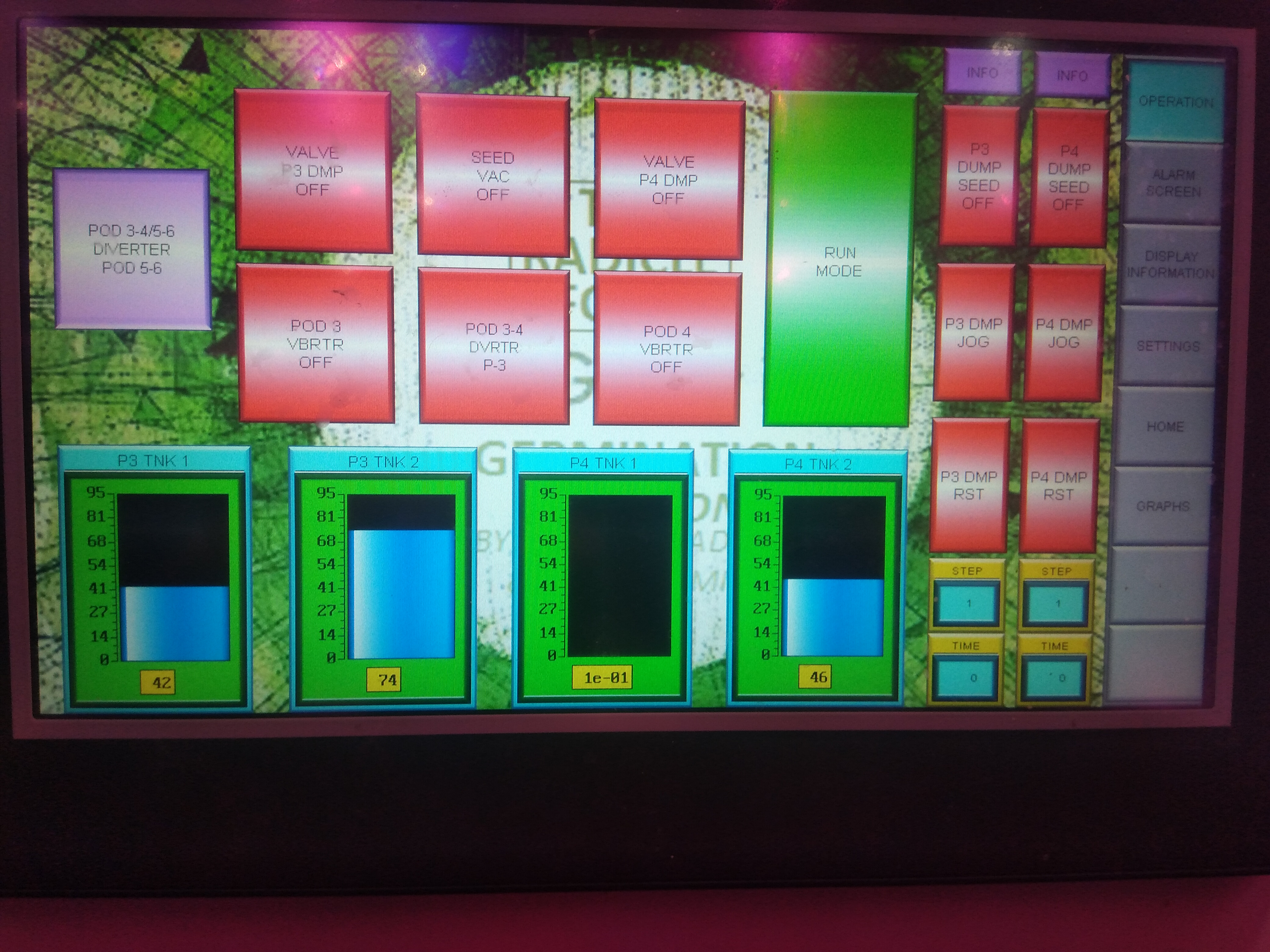

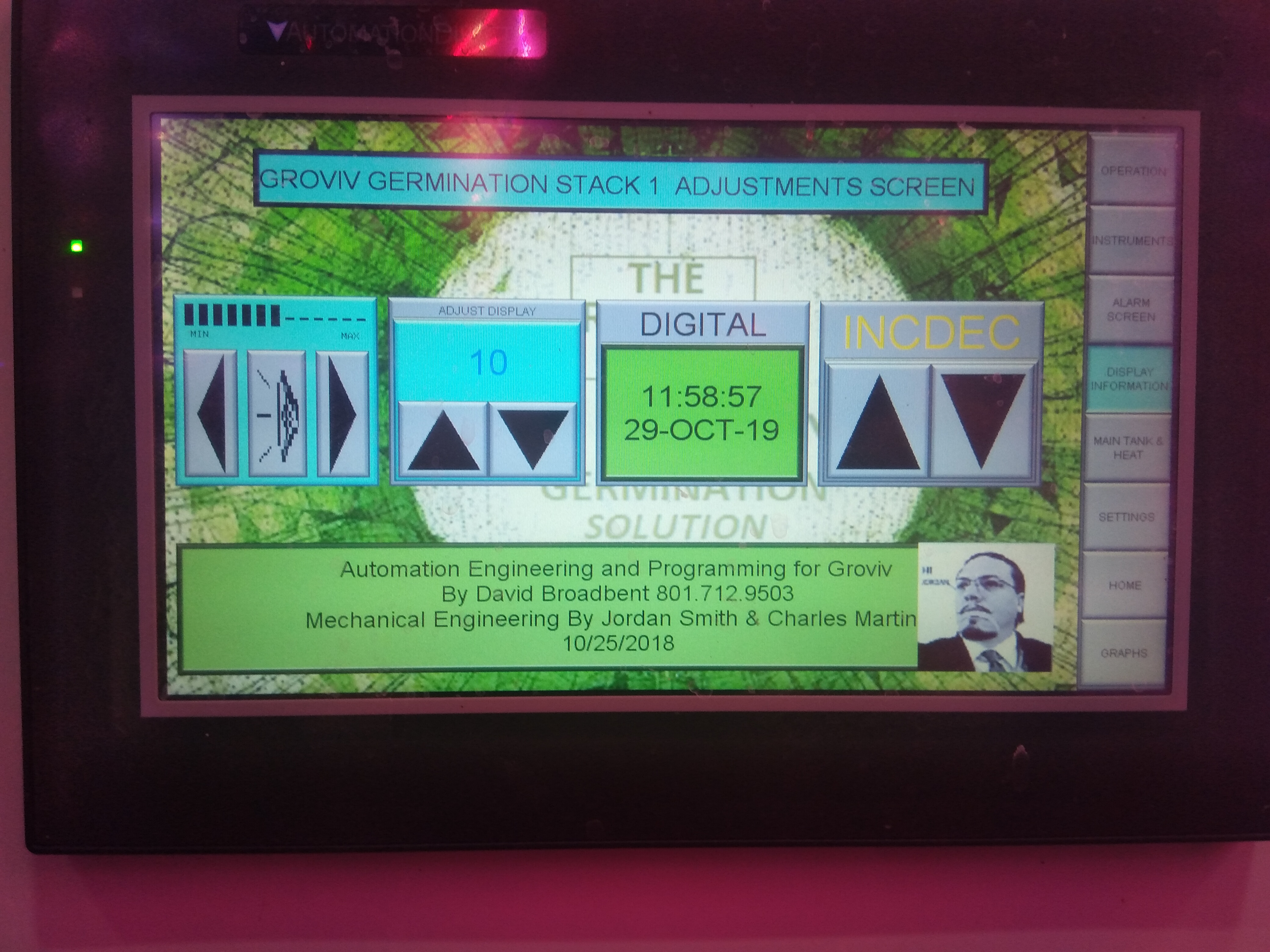

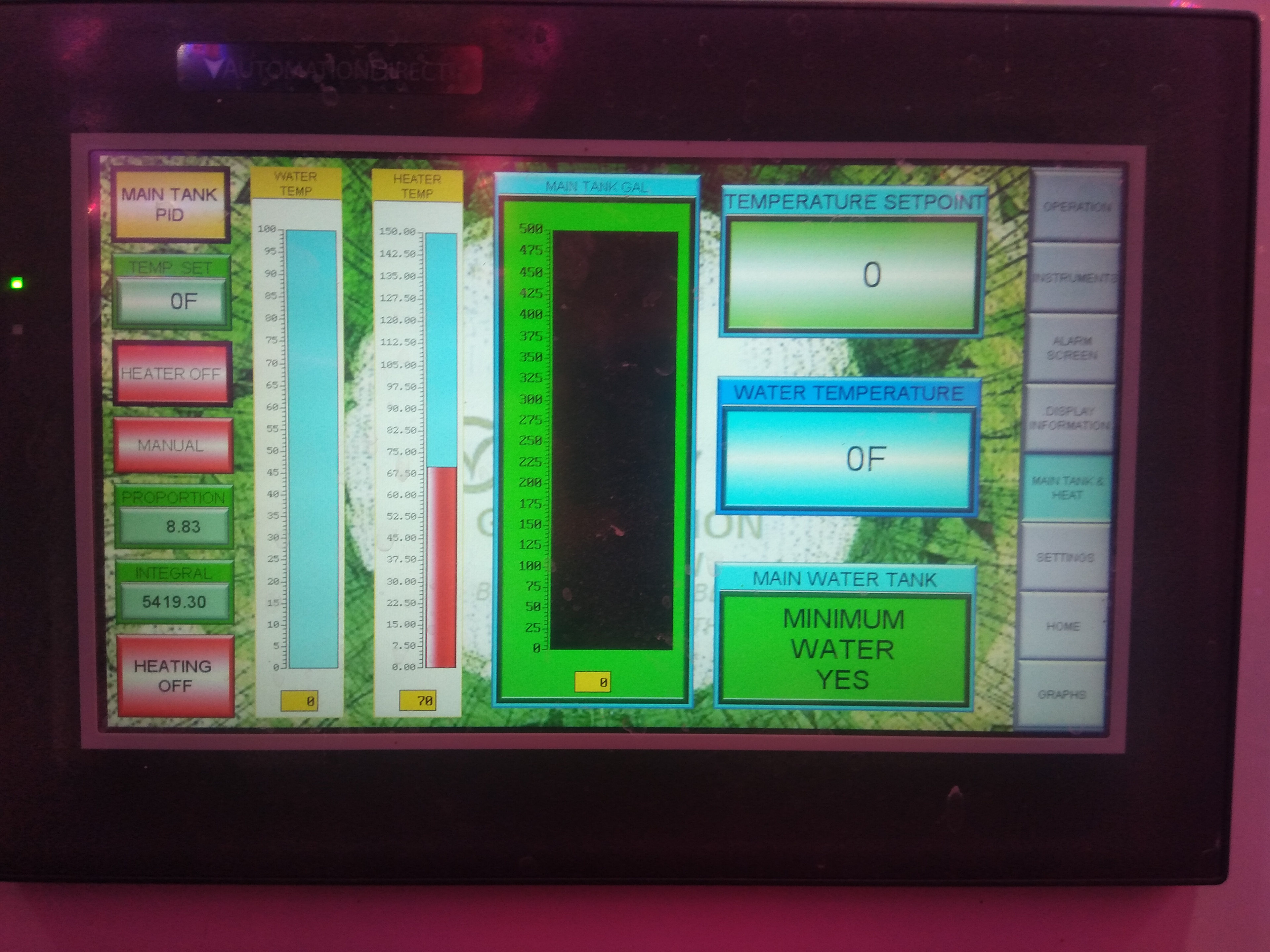

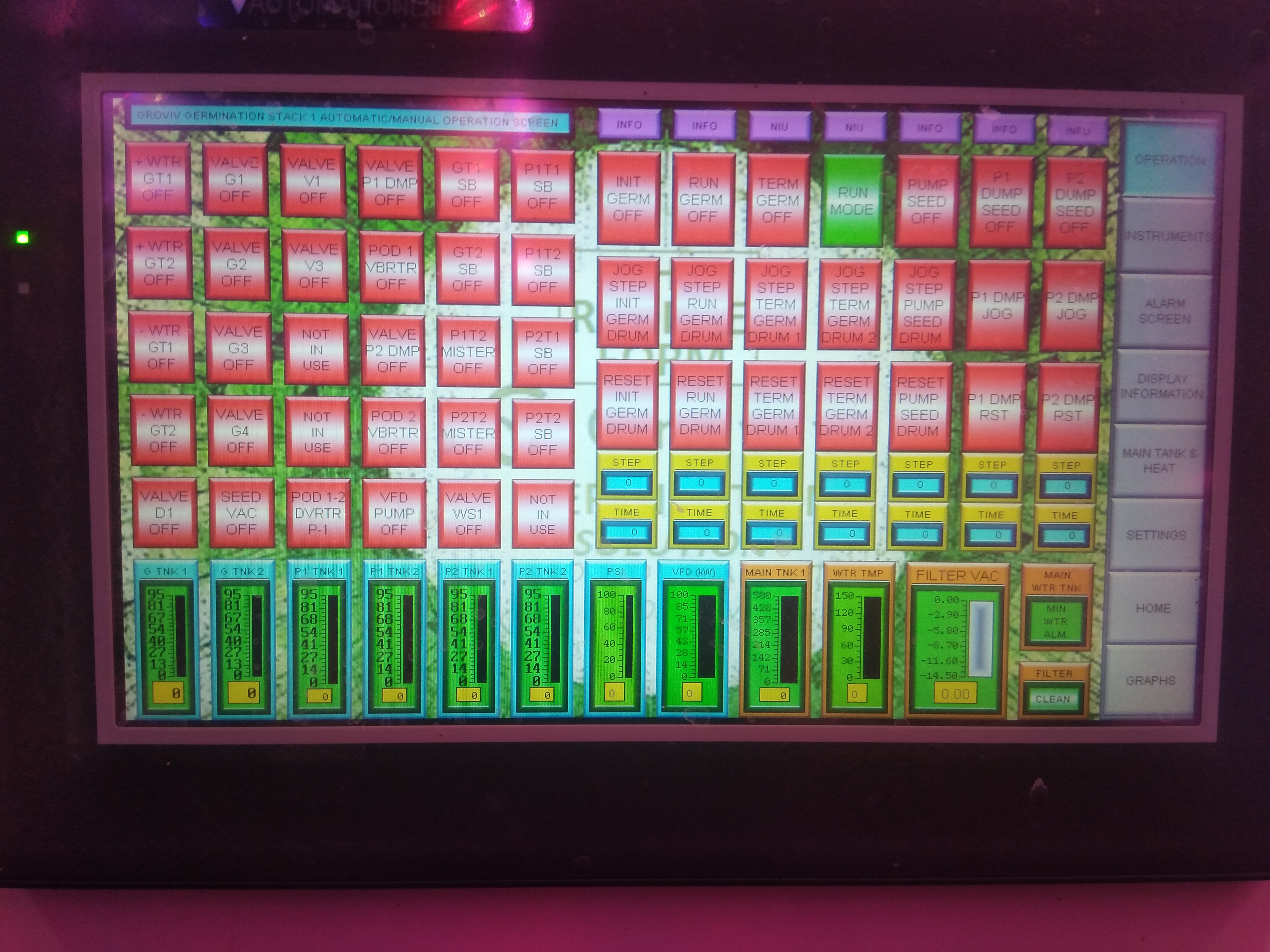

Due to the sensitive IP of the Germination process I am not allowed to show any videos or schematics/drawings. The project was engineered with a C-more EA9 series HMI and a Productivity 2000 PLC this project was built for Groviv (renamed Grov) an Environmentally Controlled Agriculture technology company

Germination tanks with controls

pumps and valves

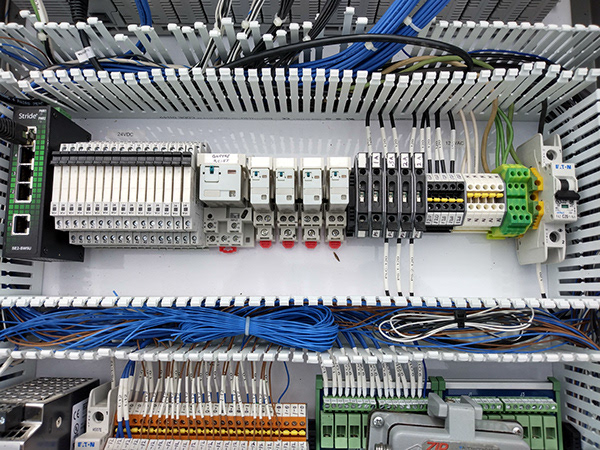

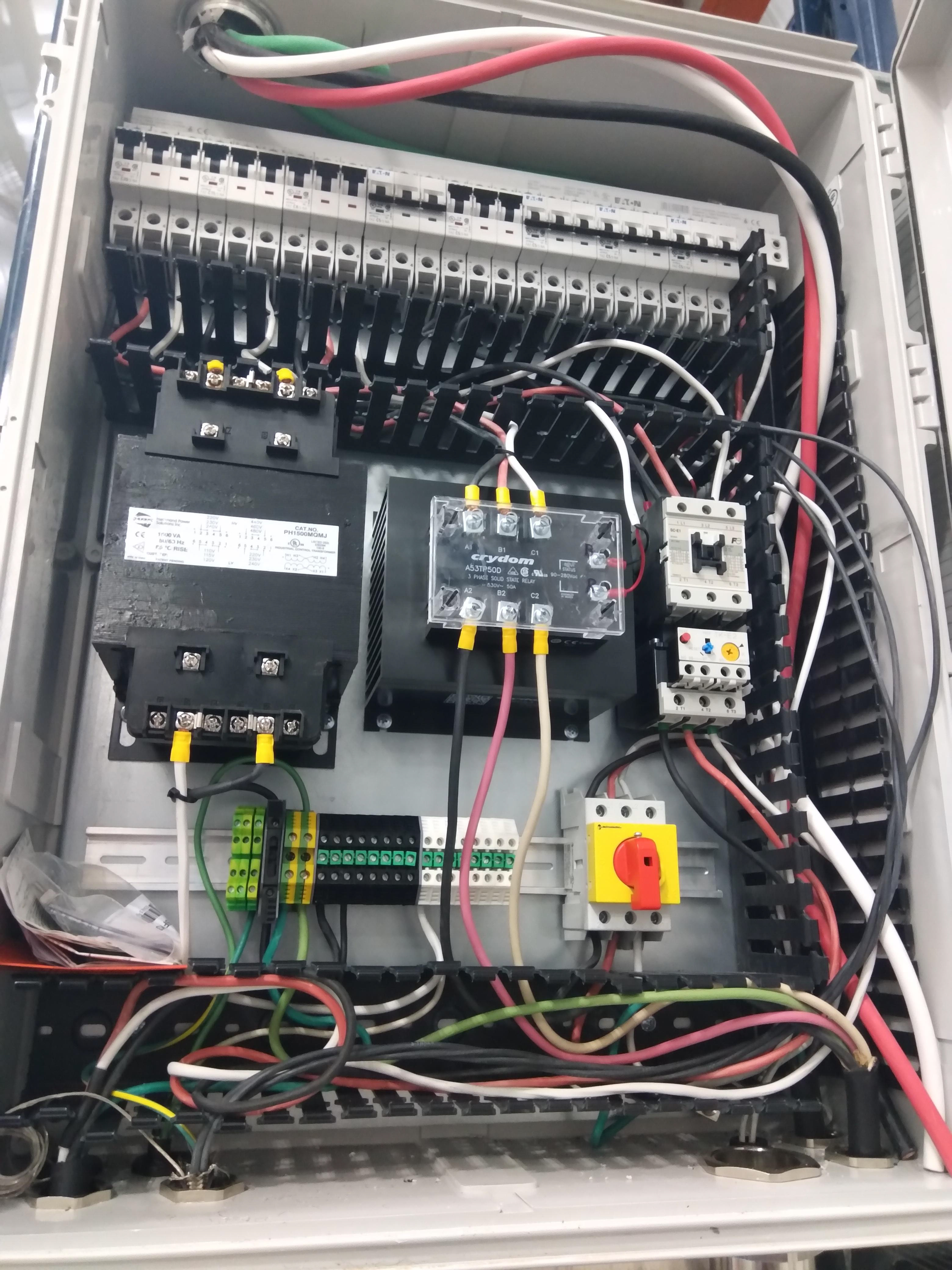

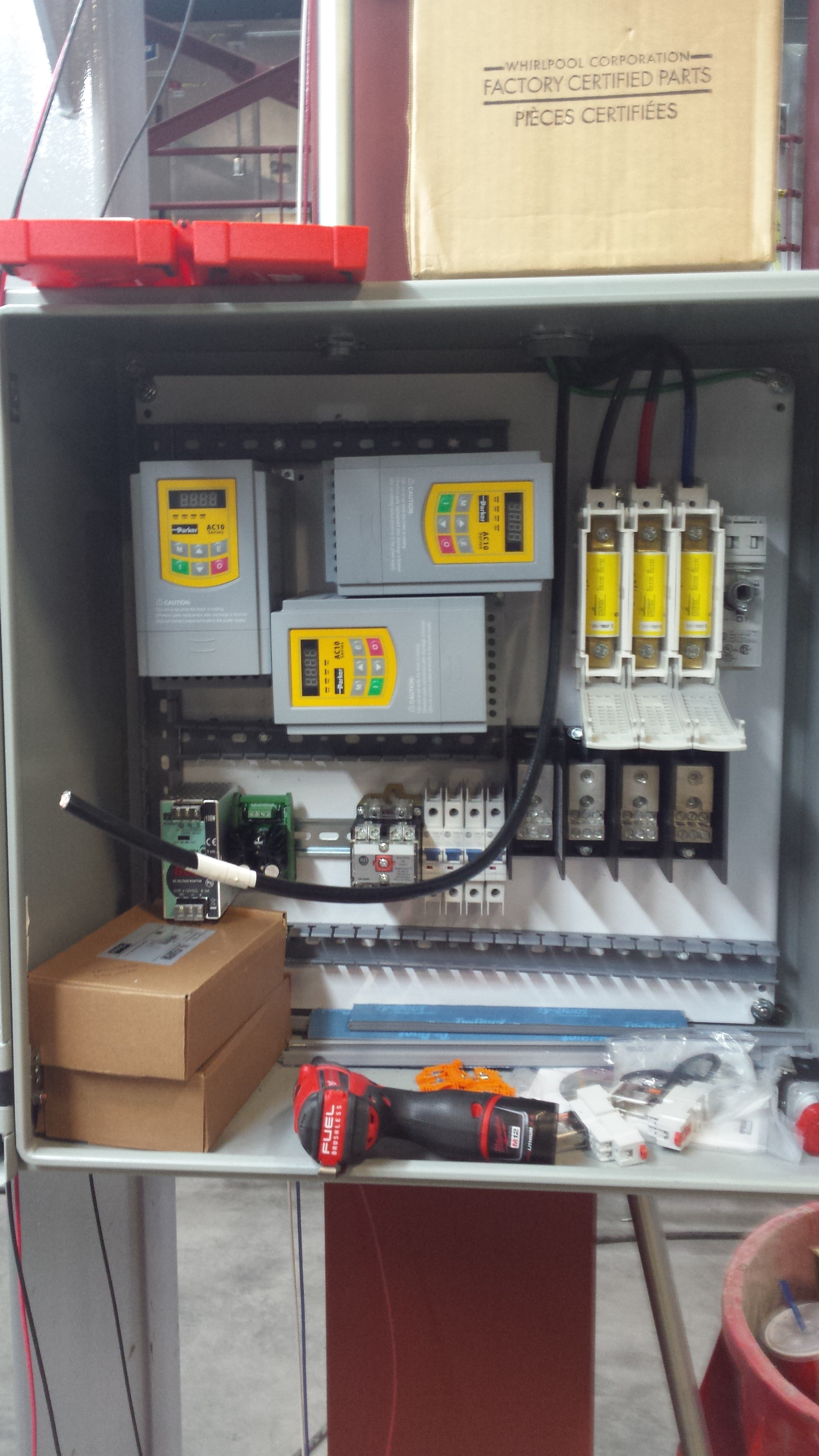

control cabinet in development

pumps and valves

power distribution in development

HMI Sensors screen

HMI instruments screen

adjustment screen with Easter egg

Temp set and PID screen

HMI operator screen

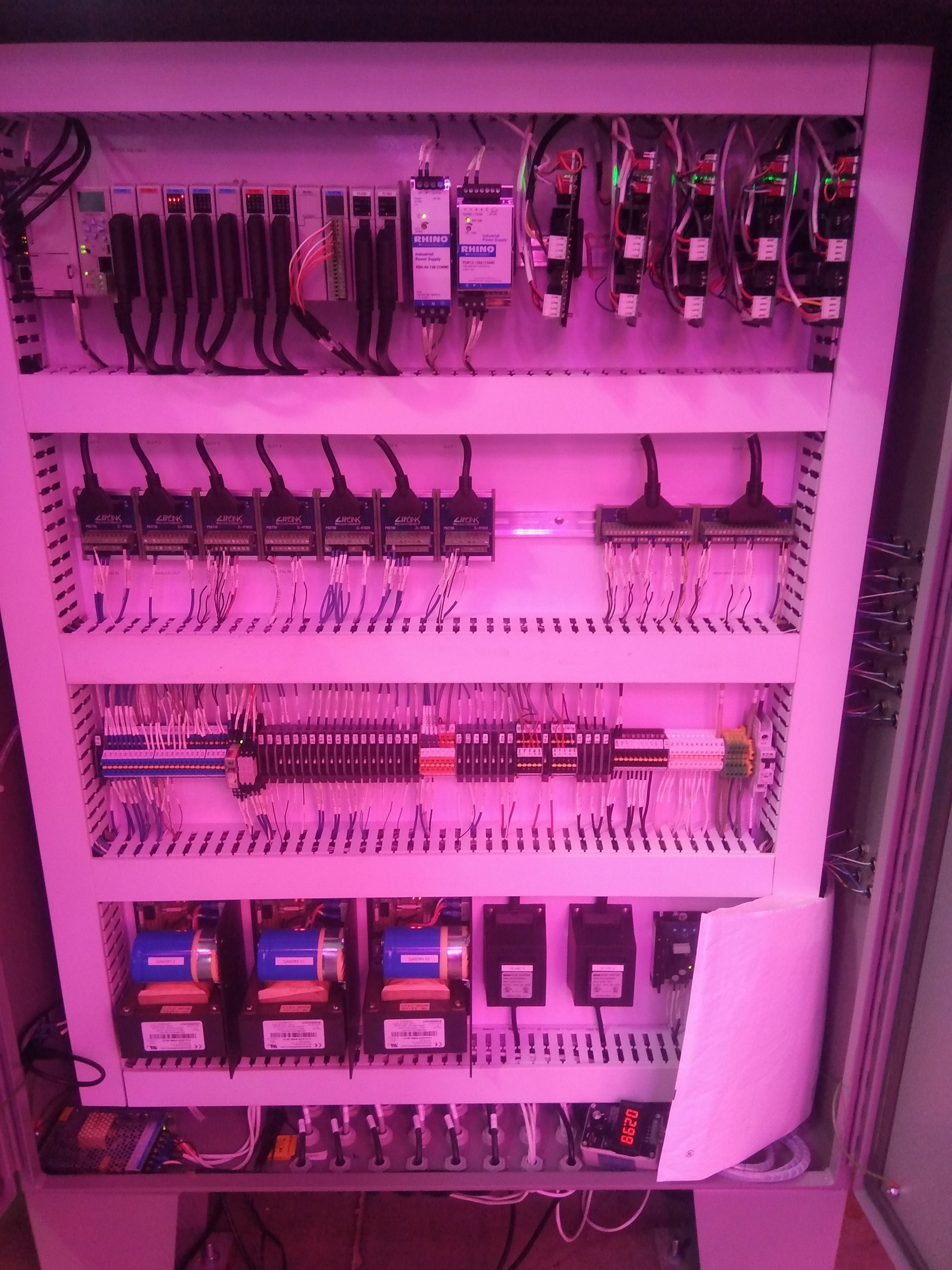

Finished control cabinet

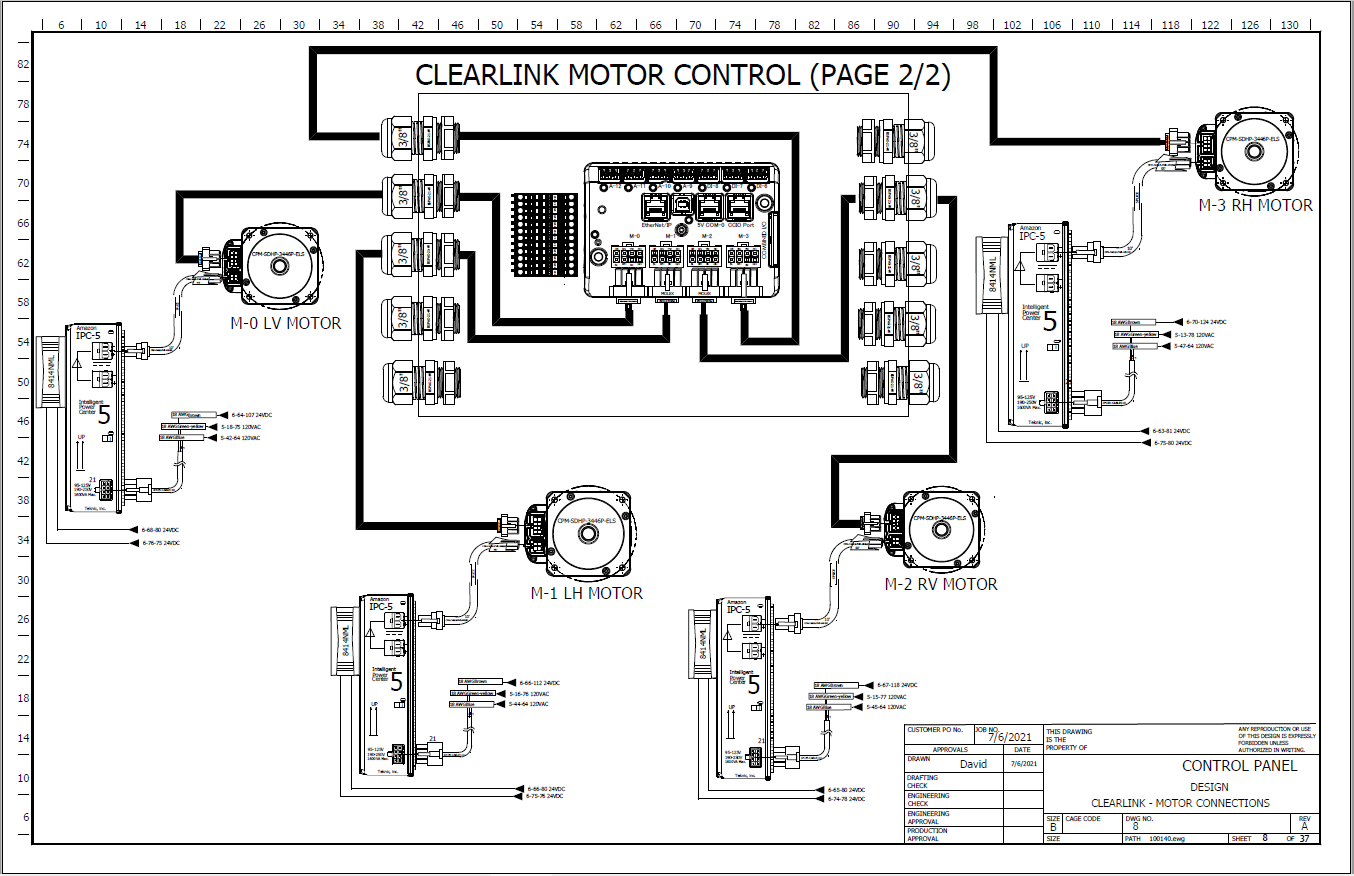

Due to the Proprietary nature of the "GUN" I cannot show pictures of the Process equipment nor video of it in operation

upgraded control cabinet

Productivity 2000

Extruder VFD

Temperature PID's

Operator screen

Operator screen

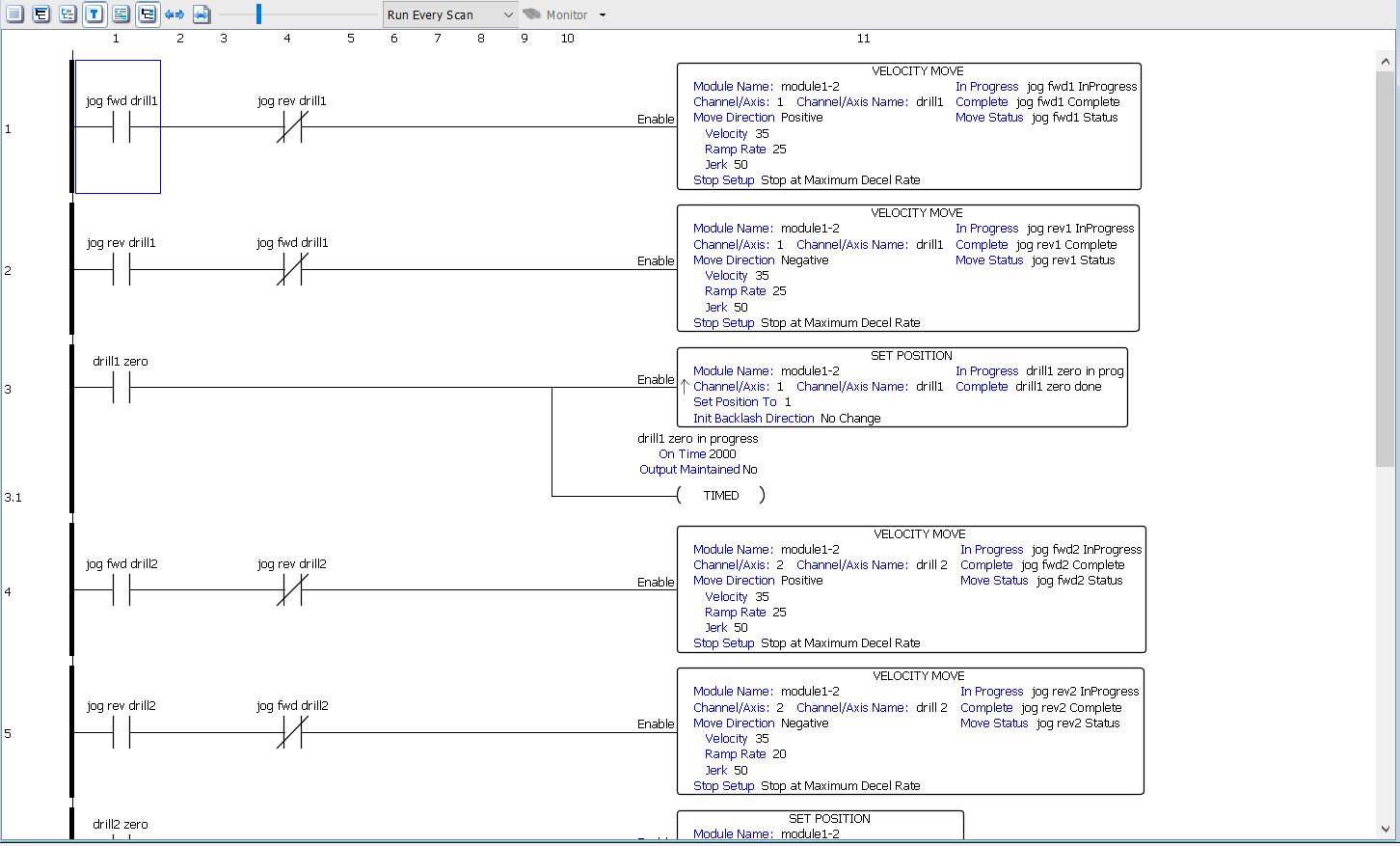

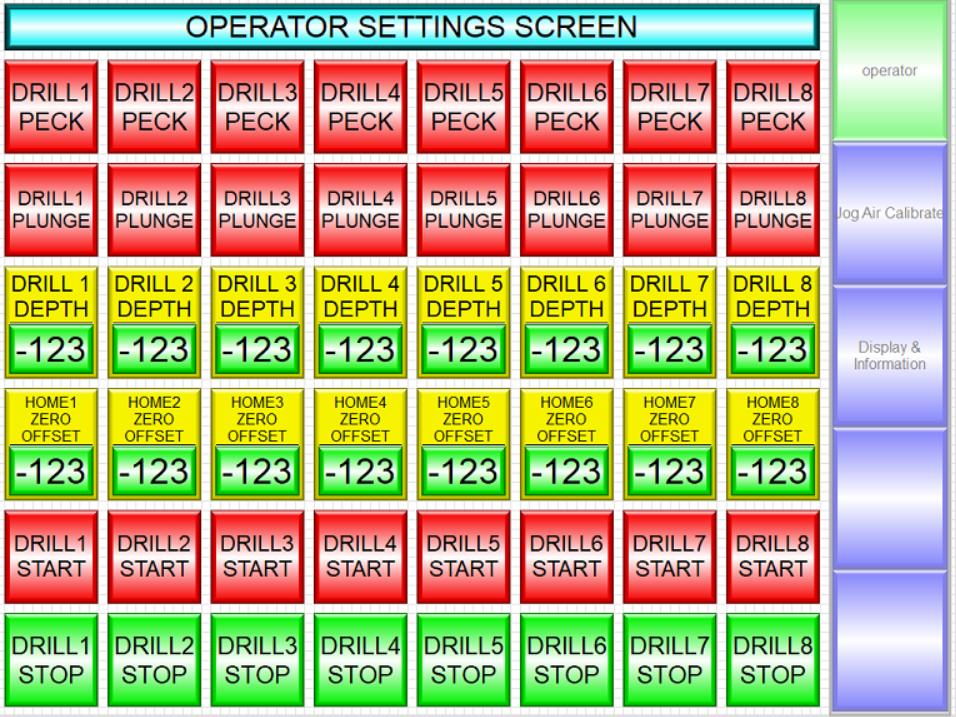

I designed the cloth dog table to port and tap a variety of different "filter plates" all of which was being done by hand at the time. it has 2 work stations a pivoting HMI and a remote pendant to start and stop operation from the far side of machine

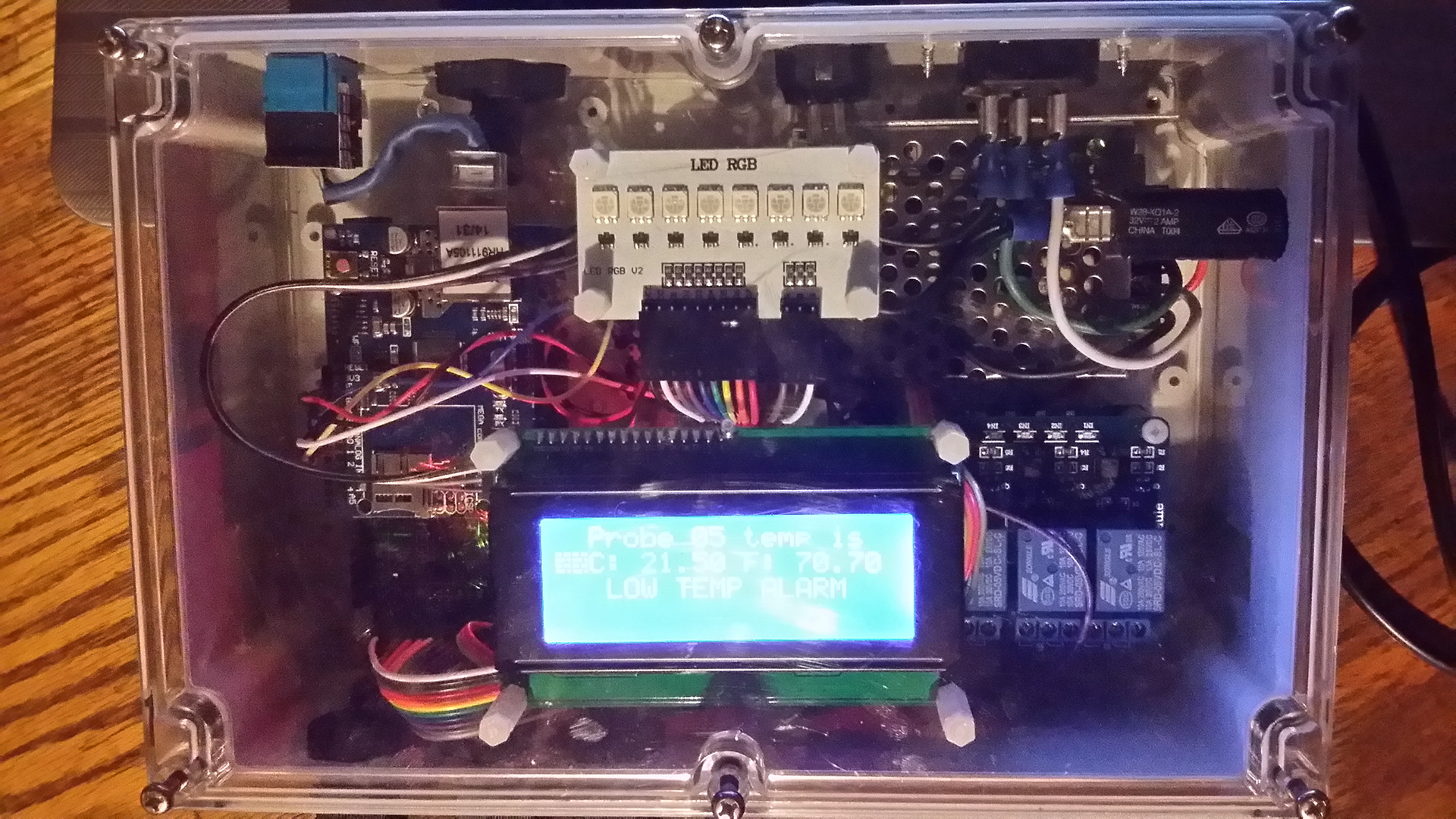

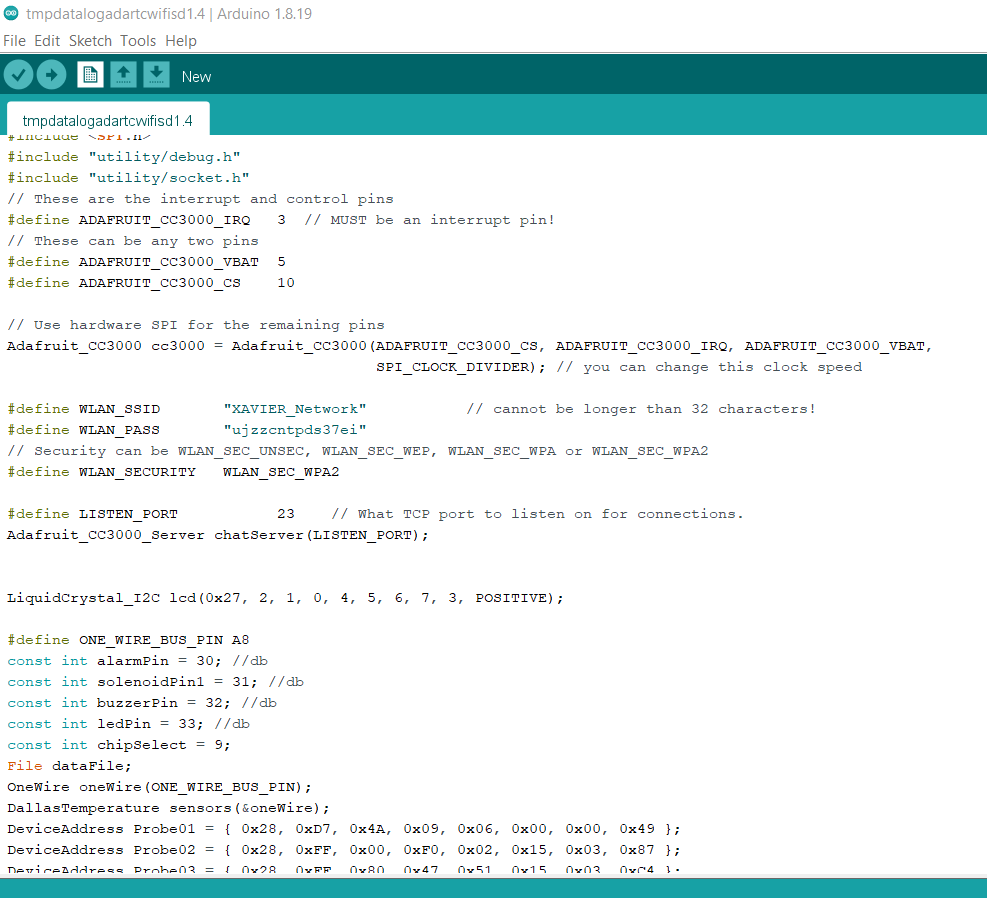

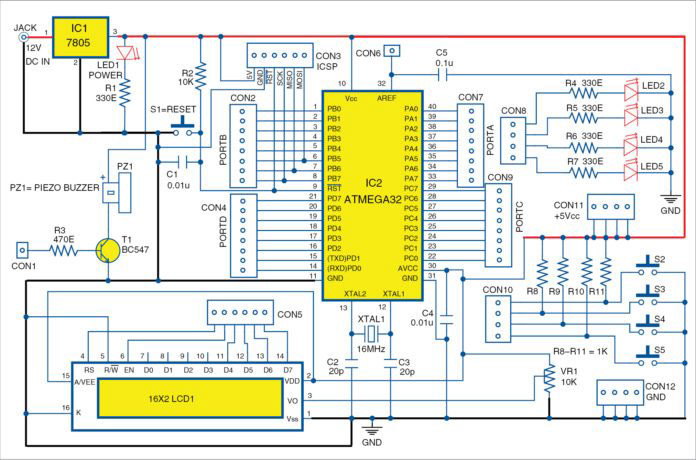

This device was designed to meet an FDA requirement that temperatures of frozen goods be tracked and logged throughout the manufacturing process. the Freezer controls and data logger used multiple RTD temperature probes to gather accurate temperatures from different levels of the freezer. i programmed in PID loops for the temperature control and it had a network interface that logged the temperatures to file locations on the server. it had remote real time viewing capabilities through telnet with built in alarms.

freezer mounting

hardware enclosure with interface

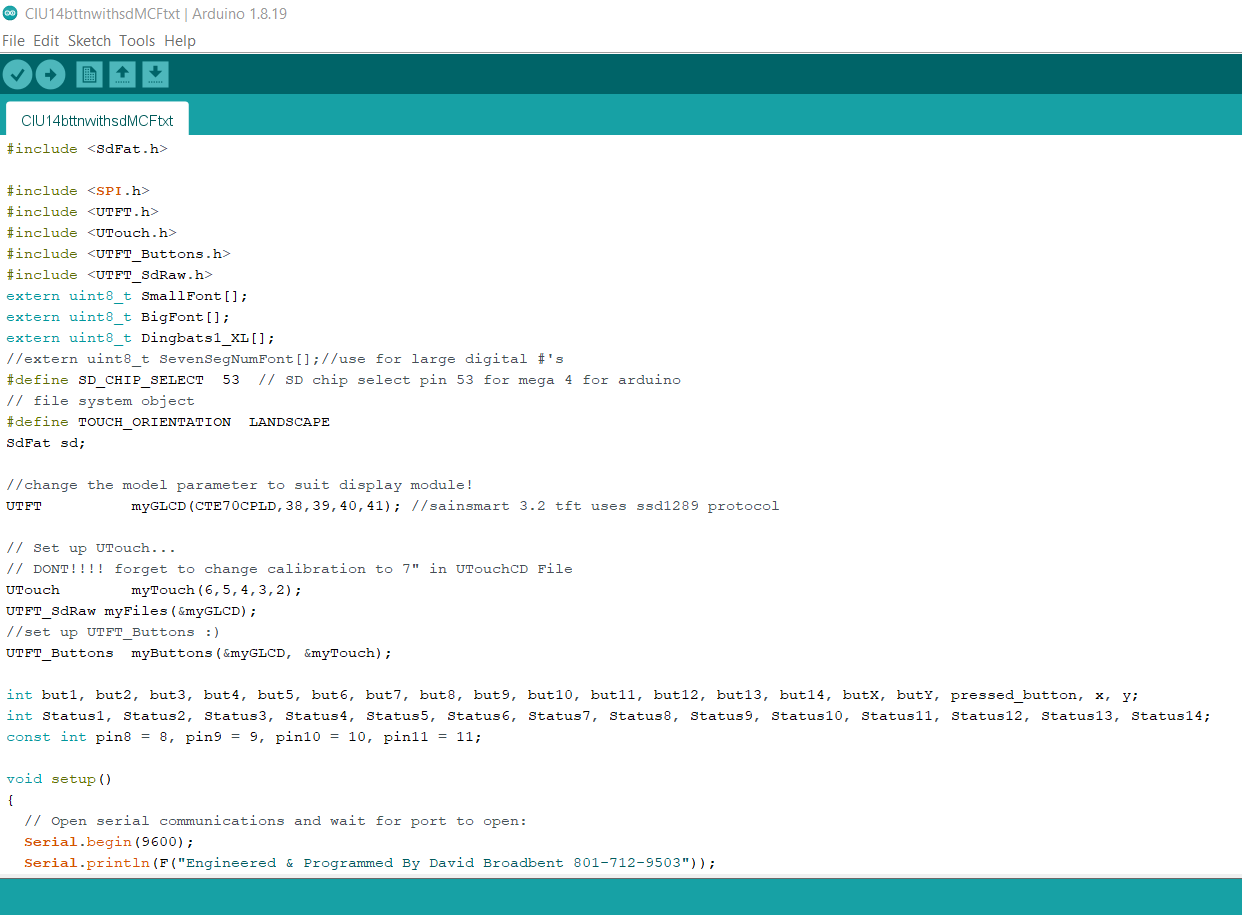

testing code

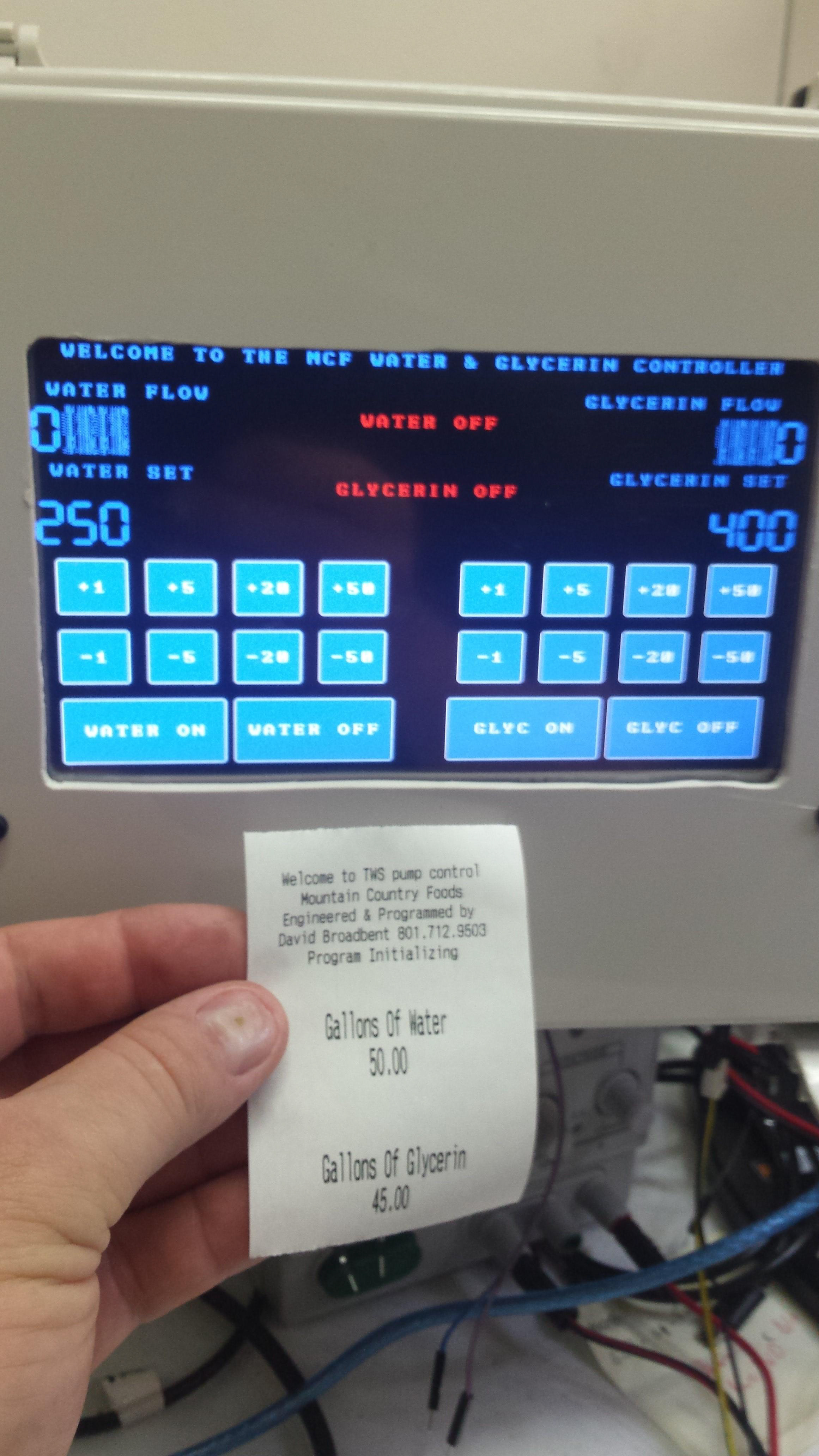

Water and Glycerin pump controls

Glycerin/Water dispenser

printed batch amount

Batch copy

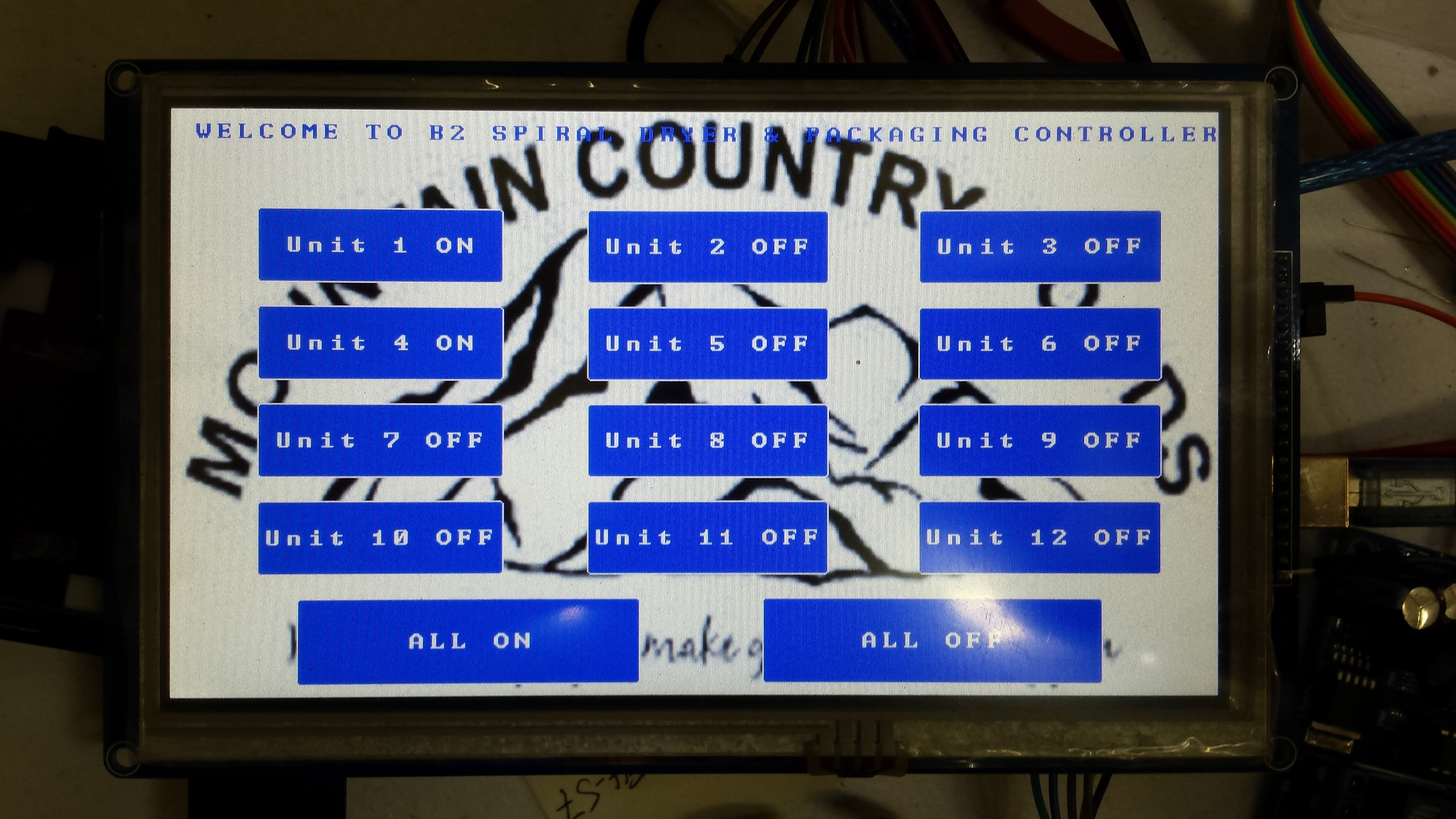

Spiral oven controls

HMI/UI

Control Cabinet

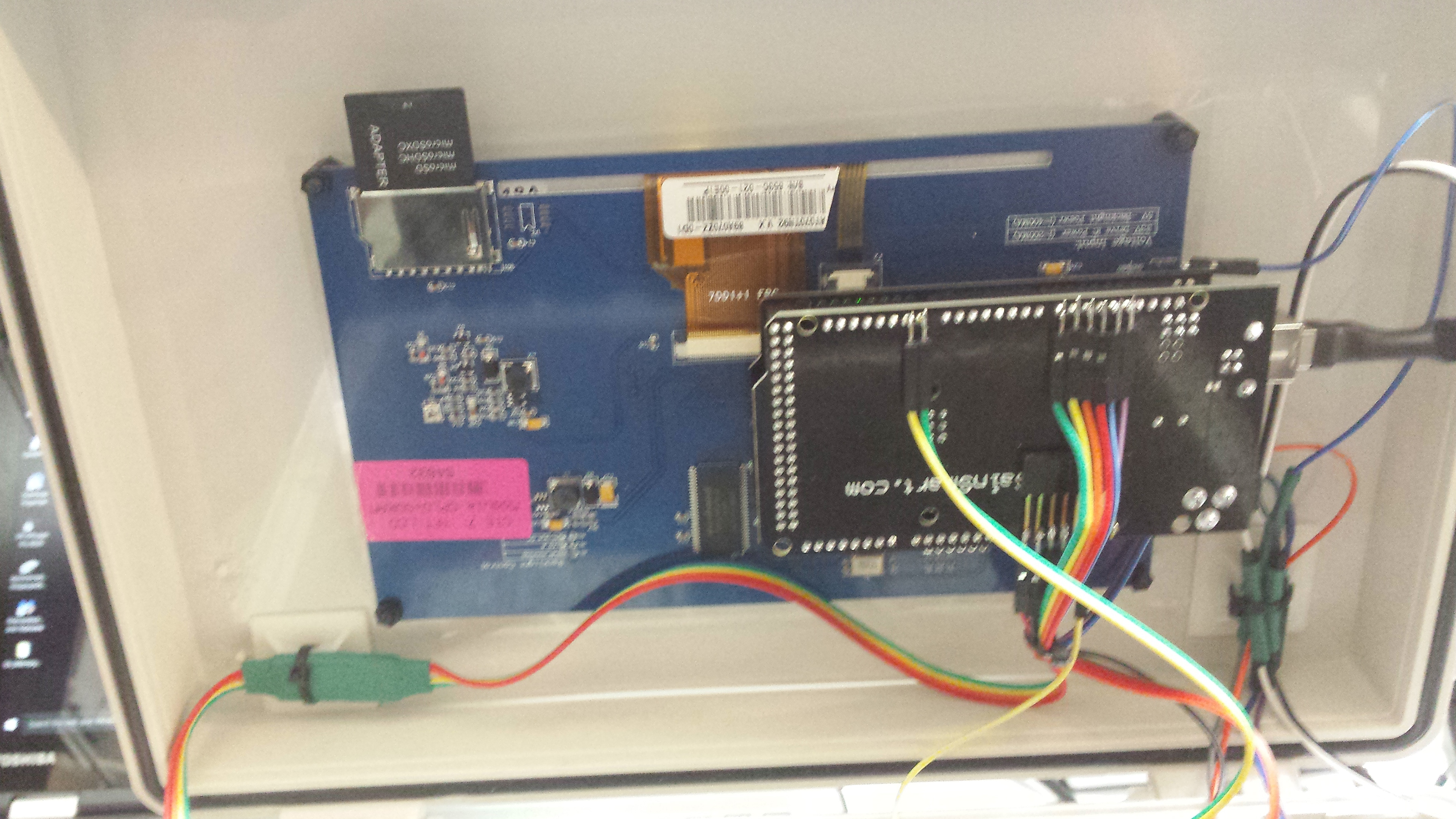

TFT LCD Touchscreen

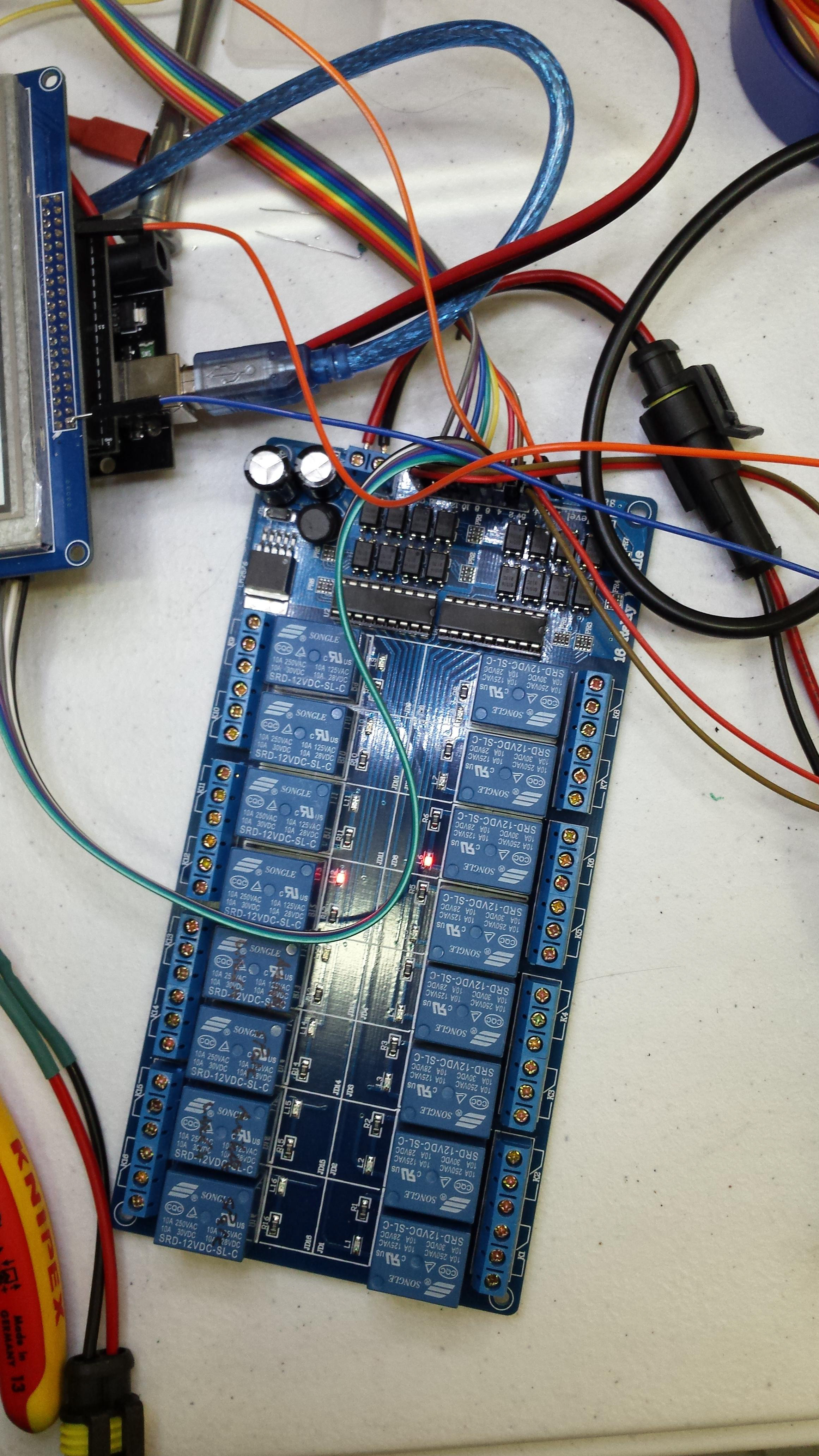

16 Point relay

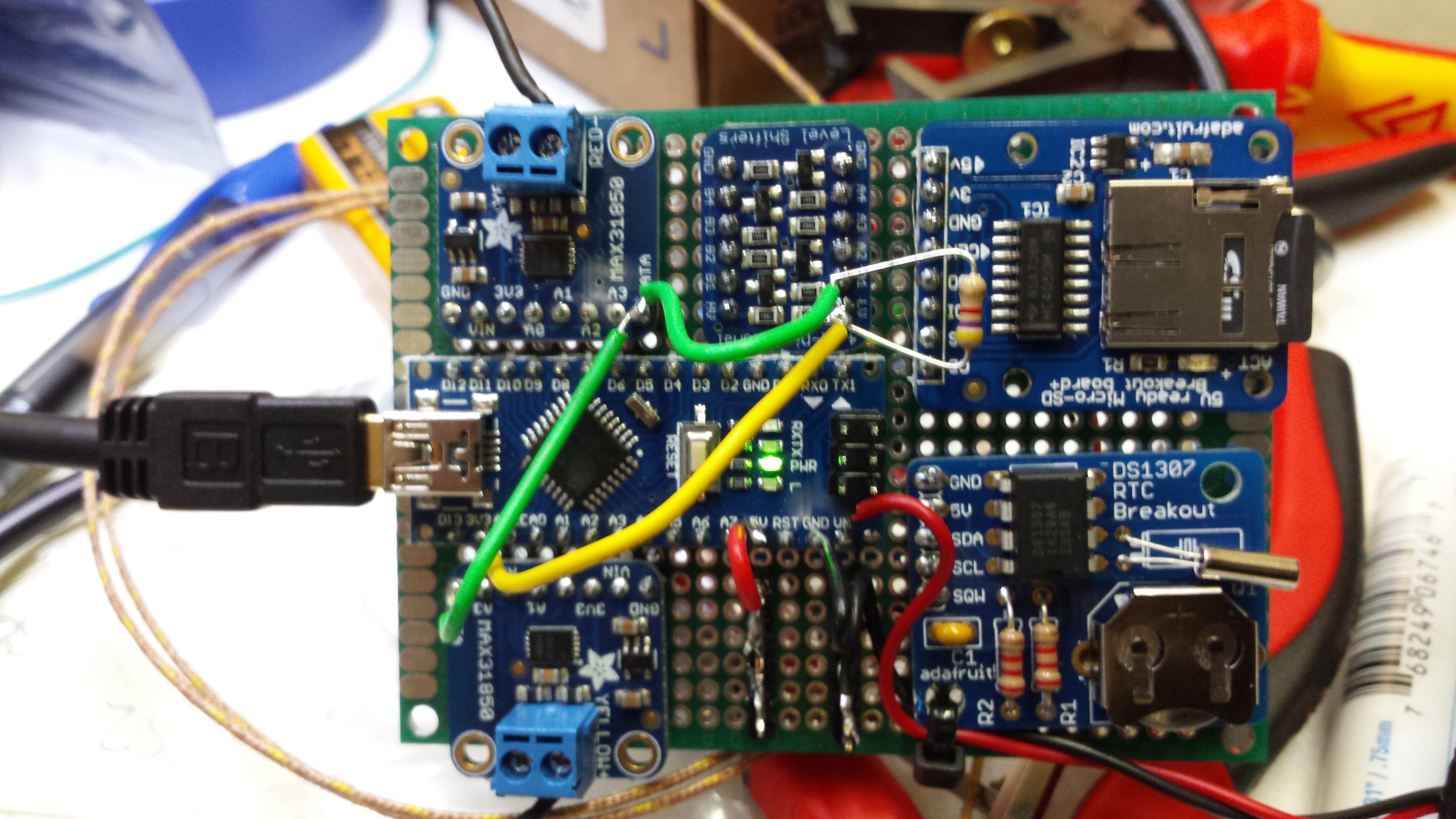

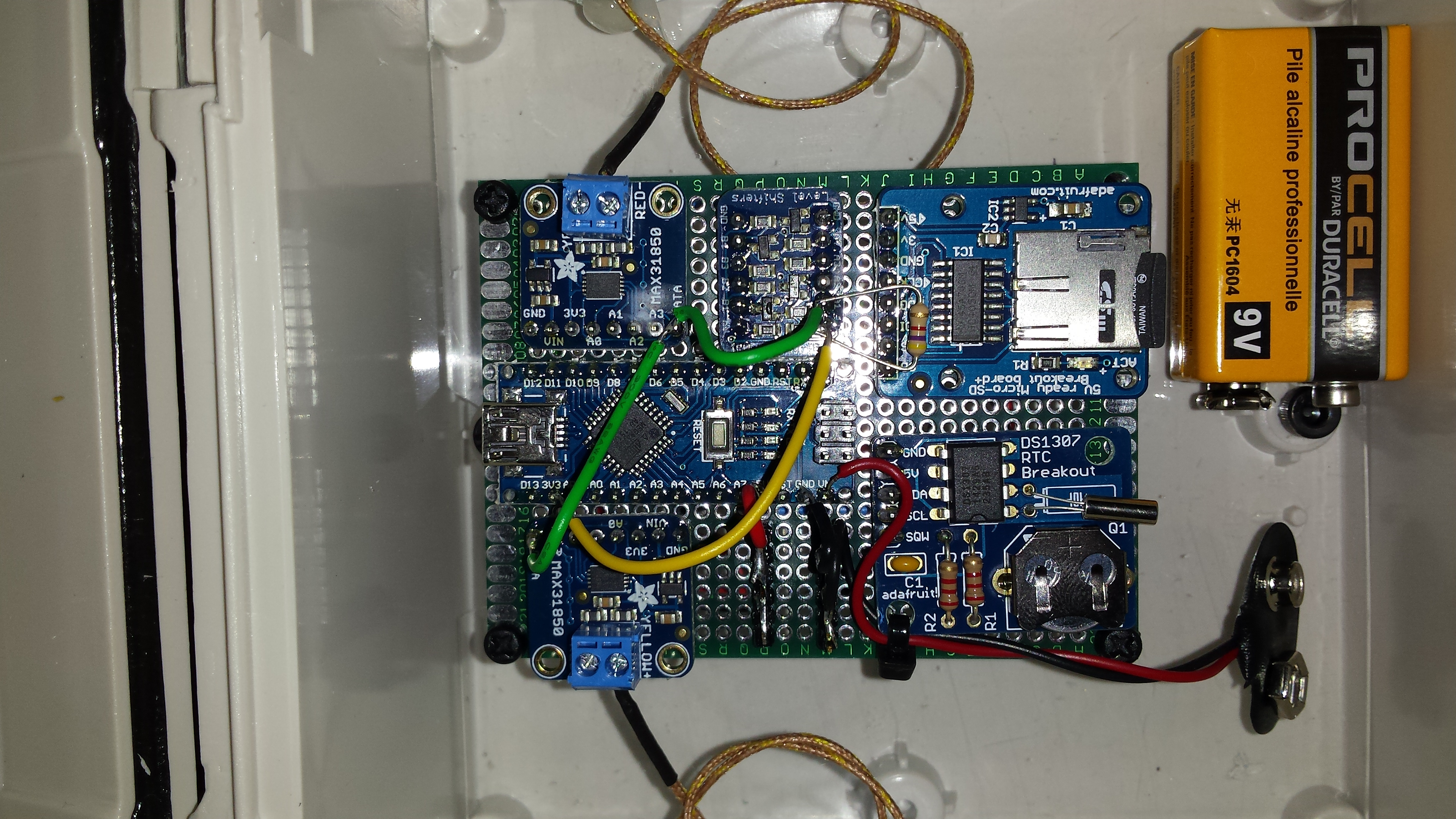

Below is a data logger I built it was capable of logging 5 channels @ 250 milliseconds per data point. 2 thermocouples, 1 pressure transducer, 1 inductive proximity sensor for RPM, and a current transducer for Amp draw, all with time and date stamps. the unit was able to be deployed in extreme environments for days of logging. the enclosure was rated NEMA 4x and was capable of withstanding extreme conditions

Proto board w/microcontroller and PCB's

Sensor array

3.5mm Jacks for sensors

LCD display

enclosure w/battery for wireless use

WAV. file player triggered by motion embedded with an amp and speakers to play any audio file uploaded at Provo Beach Resort

several capacitive proximity sensors are triggering 2 relays for animatronics on the croquet course at Provo Beach Resort

DMX controller for lights, fog and sound effects in laser tag arena. Provo Beach Resort